Consistently Updating Our Products & Technology

We have a well-equipped manufacturing plant where we manufacture a complete spectrum of hydraulic presses. Our product range includes H Frame, C type, Four Pillar Type Presses, Deep Drawing Presses, Hydraulic Power Packs, Four Column Type Fixed Frame Presses, and Four Column Type Workshop Presses.

Utilization Of Genuine Material

Sticking To Conveyance Plans

High Quality At Attractive Price

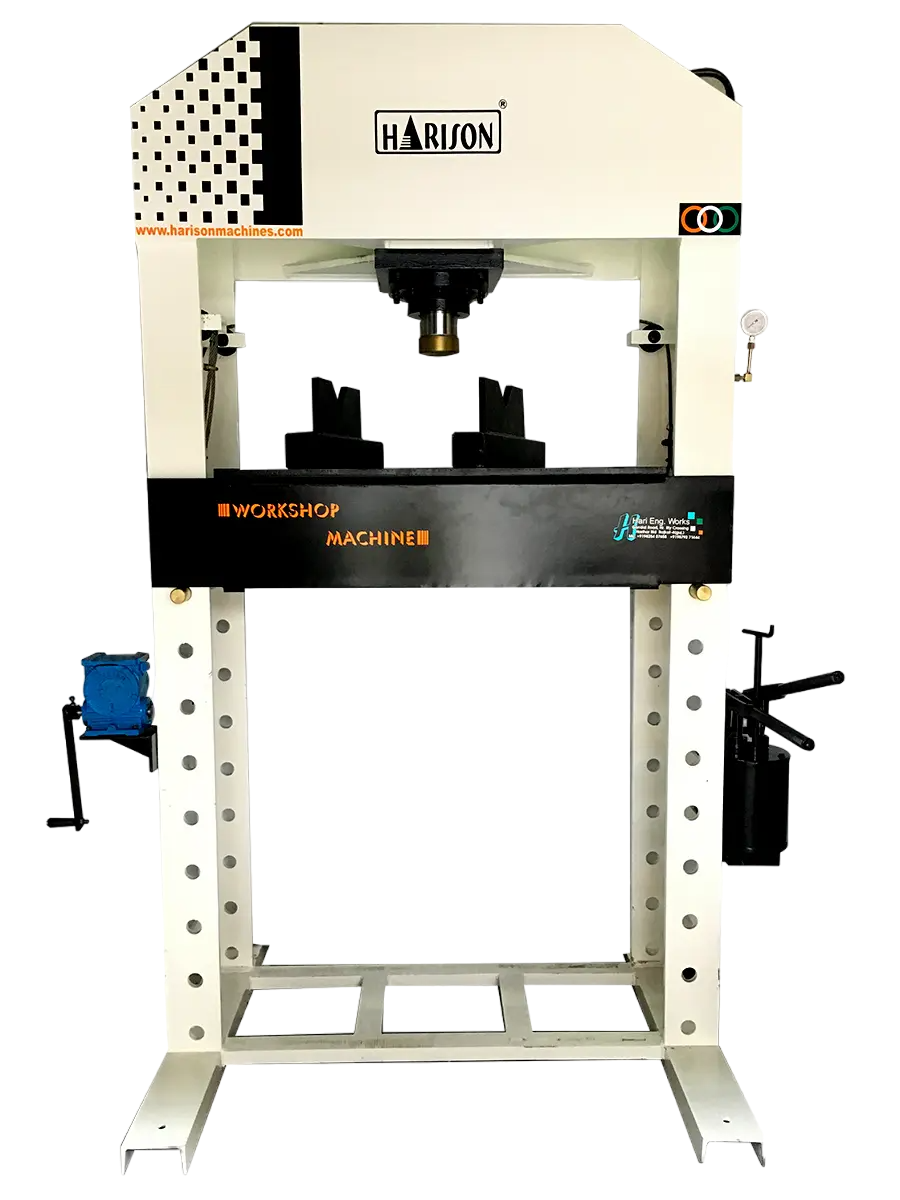

Workshop Press- Unmatched Quality, Unbeatable Prices

Looking for a high-quality workshop press to perform your industrial operations? Look no further than Hari Engineering Works!

A shop press is an essential tool commonly used in industrial, automotive, and engineering workshops. It is designed to apply a controlled amount of force through a hydraulic cylinder, enabling the user to perform various tasks such as bending, shaping, pressing, and assembling parts. These presses come in different sizes and capacities, ranging from small, manually operated models to large, industrial-grade machines.

They are invaluable for tasks that require precision and power, such as removing and installing bearings, bushings, and gears, straightening metal components, and performing complex fabrication work.

We are a frontrunner among workshop press manufacturers in India, offering a robust line of hydraulic press machines to tackle your toughest projects. We understand that workshop demands are diverse, and a one-size-fits-all approach simply won't cut it. That's why we design and manufacture shop press machines tailored to your specific needs and budget.

A shop press is an essential tool commonly used in industrial, automotive, and engineering workshops. It is designed to apply a controlled amount of force through a hydraulic cylinder, enabling the user to perform various tasks such as bending, shaping, pressing, and assembling parts. These presses come in different sizes and capacities, ranging from small, manually operated models to large, industrial-grade machines.

They are invaluable for tasks that require precision and power, such as removing and installing bearings, bushings, and gears, straightening metal components, and performing complex fabrication work.

We are a frontrunner among workshop press manufacturers in India, offering a robust line of hydraulic press machines to tackle your toughest projects. We understand that workshop demands are diverse, and a one-size-fits-all approach simply won't cut it. That's why we design and manufacture shop press machines tailored to your specific needs and budget.

Technical Specifications

| TON | DISTANCE Between Column | RAM TO BED | STROKE HAND OPERATED | STROKE POWER OPERATED | H.P. | ROD SIZE |

|---|---|---|---|---|---|---|

| 150 | 750*200 | 120 | 100 | 200 | 2 | 55 |

| 25 | 800*250 | 150 | 125 | 200 | 2 | 65 |

| 40 | 950*350 | 175 | 150 | 250 | 2 | 85 |

| 60 | 1000*400 | 175 | 150 | 250 | 3 | 100 |

| 80 | 1100*450 | 175 | 150 | 300 | 3 | 105 |

| 100 | 1200*600 | 175 | 150 | 300 | 3 | 125 |

| 150 | 1250*600 | 200 | - | 350 | 5 | 150 |

| 200 | 1300*600 | 200 | - | 350 | 5 | 200 |

| 250 | 1300*650 | 200 | - | 400 | 7.5 | 200 |

| 300 | 750*650 | 600 | 400 | 10 | 250 | |

| 350 | 750*650 | 650 | 400 | 10 | 250 | |

| 400 | 800*750 | 650 | 400 | 15 | 300 | |

| 500 | 800*750 | 800 | 450 | 15 | 300 |

Invest in a Workshop Press Built for Your Needs

We offer a variety of workshop hydraulic press options, including the highly sought-after 50-ton workshop press. We also extend our expertise to design and build presses with capacities exceeding 50 tons, catering to even the most heavy-duty applications, including the powerful 55-ton hydraulic press.

We employ high-grade materials and rigorous quality control processes to ensure your hydraulic shop press delivers long-lasting performance. Furthermore, we take pride in being one of the most competitive workshop press suppliers in India, offering exceptional value for your investment.

Tell us about your unique requirements, and our team of specialists will craft a hydraulic workshop press that seamlessly integrates into your workflow, maximizing efficiency and safety. Explore our range of hydraulic presses, or contact us now to learn more.

We employ high-grade materials and rigorous quality control processes to ensure your hydraulic shop press delivers long-lasting performance. Furthermore, we take pride in being one of the most competitive workshop press suppliers in India, offering exceptional value for your investment.

Tell us about your unique requirements, and our team of specialists will craft a hydraulic workshop press that seamlessly integrates into your workflow, maximizing efficiency and safety. Explore our range of hydraulic presses, or contact us now to learn more.

Various Applications & Features

Advance Features

High pressing force.

Precision control.

Adjustable stroke length

Robust construction.

Versatile tooling options.

Safety mechanisms.

User-friendly interface.

Customizable configurations.

Featured

Various Applications

Metal forming

Bearing fitting.

Component assembly.

Punching and stamping.

Straightening bent parts.

Riveting operations.

Bush and shaft removal.

Deep drawing processes.