Consistently Updating Our Products & Technology

We have a well-equipped manufacturing plant where we manufacture a complete spectrum of hydraulic presses. Our product range includes H Frame, C type, Four Pillar Type Presses, Deep Drawing Presses, Hydraulic Power Packs, Four Column Type Fixed Frame Presses, and Four Column Type Workshop Presses.

Utilization Of Genuine Material

Sticking To Conveyance Plans

High Quality At Attractive Price

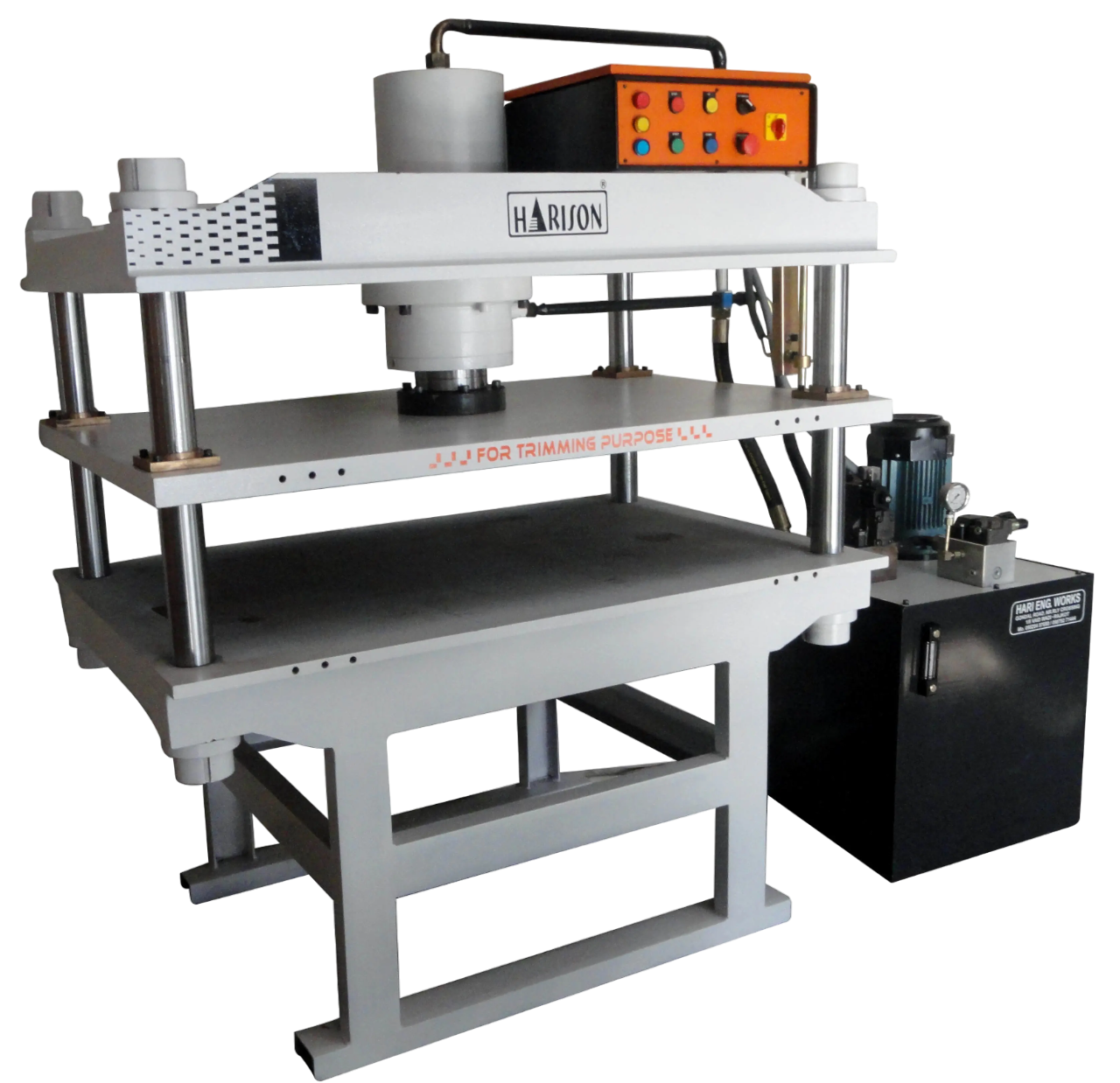

Vertical Hydraulic Press - Designed With Advanced Technology

A vertical hydraulic press is a powerful machine designed for various industrial applications, particularly in metalworking and fabrication processes. This vertical press uses a hydraulic cylinder to exert immense force in a vertical direction, allowing it to compress, mold, or shape materials with precision and efficiency.

These types of hydraulic presses are commonly used in tasks such as bending, punching, straightening, and assembling metal components. Their vertical orientation offers advantages in terms of space efficiency and ease of operation, making them essential equipment in manufacturing environments where heavy-duty forming or shaping operations are required.

Hari Engineering Works designs and builds a wide variety of hydraulic presses to meet the demands of customers. As your Vertical Hydraulic Press Manufacturers in India, we offer these machines in different configurations and frame designs including H-type press, C-type press, pillar type, etc.

These types of hydraulic presses are commonly used in tasks such as bending, punching, straightening, and assembling metal components. Their vertical orientation offers advantages in terms of space efficiency and ease of operation, making them essential equipment in manufacturing environments where heavy-duty forming or shaping operations are required.

Hari Engineering Works designs and builds a wide variety of hydraulic presses to meet the demands of customers. As your Vertical Hydraulic Press Manufacturers in India, we offer these machines in different configurations and frame designs including H-type press, C-type press, pillar type, etc.

Technical Specifications

| TON | TABLE SIZE | RAM TO BED | STROKE | H.P. | ROD SIZE |

|---|---|---|---|---|---|

| 15 | 400*250 | 275 | 200 | 2 | 55 |

| 25 | 400*300 | 300 | 200 | 2 | 65 |

| 40 | 450*300 | 350 | 250 | 2 | 85 |

| 60 | 500*350 | 400 | 250 | 3 | 100 |

| 80 | 500*350 | 450 | 300 | 3 | 105 |

| 100 | 600*450 | 450 | 300 | 3 | 125 |

| 150 | 600*600 | 500 | 350 | 5 | 150 |

| 200 | 650*600 | 600 | 400 | 5 | 200 |

| 250 | 700*600 | 600 | 400 | 7.5 | 200 |

| 300 | 750*650 | 600 | 400 | 10 | 250 |

| 350 | 750*650 | 650 | 400 | 10 | 250 |

| 400 | 800*750 | 650 | 400 | 15 | 300 |

| 500 | 800*750 | 800 | 450 | 15 | 300 |

Explore Our Range of Top Quality Vertical Hydraulic Press Machines

Our press machines are crafted from top-notch raw materials sourced from reputable vendors in the industry, ensuring durability, sleek design, and robust construction. Our well-established infrastructure is divided into specialized units to streamline our manufacturing operations seamlessly. These units include production, quality assurance, warehousing & packaging, marketing, logistics, and research & development, each managed by experienced professionals.

Our dedicated research team continually innovates production processes to maintain the high standards of our hydraulic press machines. We are the leading Vertical Hydraulic Press Exporters in India, providing high-quality machines according to the client’s needs and offering exceptional service support. Contact us now to discuss your specific requirements for a vertical hydraulic press machine.

Our dedicated research team continually innovates production processes to maintain the high standards of our hydraulic press machines. We are the leading Vertical Hydraulic Press Exporters in India, providing high-quality machines according to the client’s needs and offering exceptional service support. Contact us now to discuss your specific requirements for a vertical hydraulic press machine.

Various Applications & Features

Advance Features

Vertical design for space efficiency

Hydraulic system for precise force control

Heavy-duty steel construction for durability

Adjustable pressure settings

Customizable bed sizes for different projects

Easy-to-use control panel

Compact footprint for smaller workspaces

Integrated pressure gauge for monitoring

Featured

Various Applications

Plastic compression molding

Powder compaction for pharmaceuticals

Assembly and riveting operations

Forming and shaping of sheet metal

Compression testing of materials

Production of composite materials

Embossing and debossing of materials

Manufacturing of automotive parts